CPL-Coil rau Coil Polishing Kab

CPL-Coil rau Coil Polishing Kab

Khoom Taw Qhia

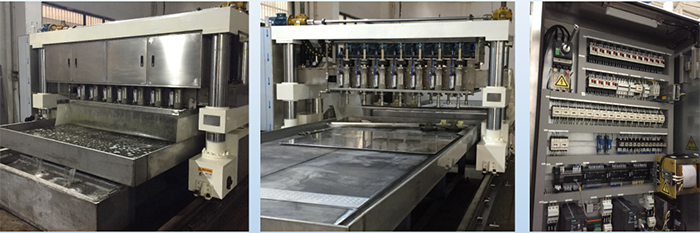

Coil rau Coil Sib Tsoo Tshuab (Nyob Hom) siv cov roj sib tsoo lossis emulsion ua Media kom ua tiav cov txiaj ntsig zoo thiab ci ntsa iab ntawm cov hlau tsis huv thiab nws tuaj yeem tshem tawm qhov tsis xws ntawm Stainless Hlau Nto.Lub Tshuab yog tsim los kom tau Finishing No.3 (Coarse Finishing, Abrasive Grain From G60 to G150) los yog No.4 (Fine Finishing, Most Nrov, abrasive grain from G180 or above) thiab HL Finishing (Hairline Finishing, Characterized by Smooth and kab ntev).

Coil rau Coil Sib Tsoo Tshuab (Nyob Hom) kuj tsim nyog rau kev kho saum npoo ntawm CRM daim hlau tom qab pickling hauv zeb;nws tshem tawm cov teeb meem me me thiab txhim kho qhov zoo ntawm cov khoom tsis raug rau Cov Khoom Siv Tsim Nyog.

Coil rau Coil Sib Tsoo Tshuab (Nyob Hom) tuaj yeem ua Stainless Hlau kauj hauv qhov ntau thiab nrog cov nplej zoo ib yam, Nws yog dav siv hauv kev lag luam high-end xws li Kho kom zoo nkauj, elevator, khoom siv hauv tsev thiab lwm yam.

Standard Coil rau Coil Hom Sib Tsoo Tshuab (Nyob Hom) yog tsim los ntawm De-Coiling thiab Re-Coiling System, 2 Lub Taub Hau Hauv Qab Grinder, 4 Lub Taub Hau Sab saum toj Grinder thiab 4 Lub Taub Hau HL Grinder.

Hauv qab Sander yog siv los tshem tawm cov kev ntxhov siab sab hauv ntawm Coil, kom ntseeg tau tias kauj yuav tsis tau deformed tom qab txiav.

4 Lub Taub Hau Sab saum toj Grinder yog los xyuas kom meej cov nplej zoo ib yam los ntawm lub taub hau coil mus rau lub taub hau coil thiab kom ntseeg tau tias qhov yooj yim hauv kev sib tsoo coils ntawm qhov sib txawv.

HL Grinder tuaj yeem ua tau raws li qhov yuav tsum tau ua los ntawm cov neeg siv khoom nrog Cov Nplej Ntshiab thiab zoo ib yam.

Sib tsoo taub hau kom muaj nuj nqis tuaj yeem ua raws li cov neeg siv khoom xav tau (IE Nws kuj tuaj yeem yog 1 Hauv Qab Grinder, + 2 Sab saum toj Grinders Etc.), lossis ib qho SB Grinder tuaj yeem ntxiv thaum kawg.

Heavy-duty tsim, Coil rau Coil Sib Tsoo Tshuab (Ntev Hom) yog tshwj xeeb los ntawm:

--- Ua tau zoo kawg nkaus Recycling System, Tsis muaj kev ua qias tuaj ib puag ncig -Cov txheej txheem rov ua dua tshiab

combines Rough Mesh Lim nrog Fine Paper Filtration, yog li sib tsoo kua ua tau

yuav siv tau zoo dua thiab rov siv dua.

--- Tsis siv neeg txoj siv taug qab thiab hydraulic / pneumatic siv tensioning xyuas kom zoo

Kev sib raug zoo thiab txo cov nqi khiav lag luam.

--- Pre-programmable execution nqis rau ib feem thickness, abrasive siv taub hau Qhov tob

thiab txhuam taub hau tob

--- Tsis Siv Neeg Thickness Kho, nrog Digital Read-Out

--- Muaj zog tshuab ncej, vibration yog zoo absorbed

--- Loj Sib cuag Cov Menyuam nrog zoo meej zoo li zoo li Dynamic Balance, Siab Spinning

Thiab Lub neej ntev ntawm Abrasive siv yog ua kom ntseeg tau

--- Kev ua haujlwm siab dua, nrog kev siv hluav taws xob tsawg-30% lub zog tuaj yeem txuag dua li lwm yam

tshuab.

--- Kev hloov ceev ntawm Abrasive Belts

--- Tus nqi zoo tshaj plaws

Cleaning thiab Drying System:

--- Kev Tsim Nyog Tsim, Cov Ntsiab Tseem Ceeb yog tag nrho ua nrog Stainless Hlau, Lub Neej Ntev tuaj yeem ua tau ntau dua

tshaj 20 Xyoo Ntxiv.

--- Recycling Water Tank, Tsim tshwj xeeb, 30% Dej tuaj yeem txuag tau

--- Nws pib cua sov thiab kub-kub System, 70% Fais fab tuaj yeem txuag tau.

--- High Power Blower kom tsis txhob muaj dej cim tom qab ziab.

--- Direct Lamination tom qab ziab, Zaj duab xis Tension thiab Braking System, Nws pib zaj duab xis txiav

nrog high efficiency.Zaj duab xis npuas dawb.

Kab Transmission thiab De-Coiler thiab Re-Coiler nro Control System

--- Kis Servo Tsav: AC Control, 30% Fais Fab Txuag

--- De-Coiler thiab Re-Coiler tuaj yeem qhib los ntawm ob sab hauv qab lossis sab saum toj, Nws ua haujlwm rau Coil los ntawm

txhua lub zeb hauv ntiaj teb.

--- Re-Coiler Tension Unit yog peb Kev Tsim Kho Tshwj Xeeb, Kev ruaj ntseg tau txhim kho zoo heev.

Qhov zoo ntawm ZS CPL

1. Cov neeg muab kev daws teeb meem, ZS muab cov kab tiav suav nrog Unwinder, Rewinder, Loading Car, Pinch Roll, Flattener, Crop Shear, Washing and Drying system, PVC coater.Tib lub sijhawm peb muab Coolant Lim thiab Recycling System, Mist Collector, Hluav Taws Xob Hluav Taws Xob thiab Tshuab Briquetting.2. Tsis muaj qhov tsis xws luag thiab chatter cim los ntawm kab 3. Kab nrawm mus txog 40m / min max.

4. Kab yog tsim rau 24 teev tas li ntau lawm

5. Qib siab ntawm Automation, piv txwv li Load tas li.Vuam Seam Tracking System (yeem muab nrog welder)

6. Kev ua haujlwm thiab kev saib xyuas tus phooj ywg

| Khoom siv: | Stainless hlau coils | |

| Max khoom tensile zog: | N / hli2 | -850 |

| Min / Max khoom thickness: | mm | 0.4-3 |

| Sawb dav min / max: | mm | 600-1600 Nws |

| Max coil hnyav ntawm qhov nkag: | t | 30 |

| Entry coil sab nraud txoj kab uas hla min / max: | mm | 1000-2100 Nws |

| Entry coil internal txoj kab uas hla: | mm | 508/610 ib |

| Max coil hnyav ntawm qhov tawm: | t | 30 |

| Exit coil txoj kab uas hla min/max: | mm | 1000-2100 Nws |

| Exit coil internal txoj kab uas hla: | mm | 508/610 ib |

| Kab ceev: | m/min. | Max.40 rau rewinding.5-35m / min rau kev ua |

CPL feem ntau yog siv rau kev tshem tawm cov teeb meem me me hauv txias dov SS coil hauv ntub dej, tau txais cov khoom zoo nkauj, xws li No.3, No.4, HL, SB & Duplo.Lub coolant tuaj yeem yog emulsion lossis ntxhia roj.Coolant filtration thiab recycling system yog qhov tseem ceeb rau txoj kab tiav.ZS CPL yog tsim los rau txias dov kauj rau coil ua li ntawm 100 mus rau 1600 hli dav thiab ib tug tuab ntawm 0.4 mus rau 3.0 hli.WUXI ZS kuj muab CPL qhuav.Cork txoj siv yuav raug siv kom tau qhov ua tiav zoo ib yam li Scotch-Brite xov (SB), pub ceev ceev ntawm CPL qhuav tuaj yeem yog 50m / min lossis ntau dua.

Daim ntawv thov:

Kev siv NO.4 & HL suav nrog: of elevator, Escalator, sab hauv cladding, tsev facades, Khoom siv hauv tsev, thiab lwm yam.

Kev kho mob ntxiv yog ib txwm ua tiav raws li No.4 thiab HL nto: PVD Xim, Etched Pattern, Anti-Finger Print Processing, Rau npe ob peb, yog qhov ntau tshaj plaws.

Tuam txhab Taw Qhia

Peb keeb kwm:

Cov kws tshaj lij rau Flat Surface Abrasives Belt Sib tsoo ntawm Hlau: Lub hom phiaj no yog coj peb mus rau kev tshawb fawb hauv cov hlau sib tsoo thiab polishing los ntawm coated abrasives teb los ntawm 1990s.

Nyob rau hauv 2005 peb pib tsim, tsim thiab assembling dav abrasives siv sib tsoo tshuab rau hlau.Nrog kev nthuav dav ntawm kev lag luam thiab kev hloov pauv ntawm cov tswv cuab cov qauv,

nyob rau hauv 2015 WUXI Zhongshuo Precision Machinery Co., Ltd tau tsim.

Peb lub tuam txhab:

Peb yog ib tug tswv tswj mid-size tuam txhab.Lub tuam txhab nyob hauv Wuxi City, Jiangsu Province.Cov peev txheej sau npe yog 8 lab RMB.Qhov kev tsim kho thaj tsam tshaj 7000 m2.Tag nrho cov neeg ua haujlwm yog 52, suav nrog 1 Kev Tshawb Fawb Qib engineer, 2 tus kws tshaj lij engineers thiab 5 engineers.Peb muaj cov kws tshaj lij tsim, tsim khoom, sib dhos, teeb tsa, commissioning thiab pab pawg muag khoom.

Peb cov khoom

Peb tsim siv dav siv sib tsoo thiab polishing tshuab, txhuam tshuab, daim iav xov tshuab, vibration xov tshuab, embossing tshuab rau hlau kauj thiab daim ntawv, nrog rau kev nkag thiab tawm ntawm CGL (Coil rau Coil Kho Kab Sib Tsoo rau Steel Maker) thiab CPL (Coil mus rau Coil Polishing Line for Service Center), xws li Unwinder, Rewinder, Loading Car, Pinch Roll, Flattener, Crop Shear, Coolant Filtration and Recycling system, Washing and Drying system, Mist Collector, Fire Fighting system.Peb kuj muab Loading device nrog Nqus Khob Pab Pawg rau Cov Ntawv rau Sheet Sib Tsoo Lin

Peb cov neeg siv khoom:

Peb cov npe siv suav nrog Tisco Daming, Wuxi Puxin, Zhejiang Bohai thiab lwm cov neeg siv khoom hauv Suav teb.Peb xa peb cov khoom mus rau Tebchaws Europe xws li Ltalis, Qaib Cov Txwv nrog CE Certification.Peb kuj muab txoj siv calibrating grinder rau Suav tuam txhab uas muab cov khoom siv rau Aircraft thiab Nuclear In.

Peb Daim Ntawv Pov Thawj

Tej yaam num

Txhawm rau tsim kom muaj txiaj ntsig rau cov neeg siv khoom yog peb qhov kev nrhiav tas li.Koj qhov kev txaus siab yog lub zog ntawm peb qhov kev hloov pauv tas mus li.

CPL-Coil rau Coil Polishing Kab rau Stainless Steel Service Center

Client:浦新金属

CPL feem ntau yog siv rau kev tshem tawm cov teeb meem me me hauv txias dov SS coil hauv ntub dej, tau txais cov khoom zoo nkauj, xws li No.3, No.4, HL, SB & Duplo.Lub coolant tuaj yeem yog emulsion lossis ntxhia roj.Coolant filtration thiab recycling system yog qhov tseem ceeb rau txoj kab tiav.ZS CPL yog tsim los rau txias dov kauj rau coil ua li ntawm 100 mus rau 1600 hli dav thiab ib tug tuab ntawm 0.4 mus rau 3.0 hli.WUXI ZS kuj muab CPL qhuav.Cork txoj siv yuav raug siv kom tau qhov ua tiav zoo ib yam li Scotch-Brite xov (SB), pub ceev ceev ntawm CPL qhuav tuaj yeem yog 50m / min lossis ntau dua.

SPL-Daim ntawv rau Sheet Polishing Kab (Ntev hom)

Client:太钢大明

Sheet to Sheet Grinding Machine (Wet Type) siv cov roj sib tsoo los yog emulsion ua Media kom ua tiav cov kev sib tsoo zoo thiab ci ntsa iab ntawm kub lossis txias dov stainless hlau los yog coils.Lub Tshuab yog tsim los kom tau Finishing No.3 (Coarse Finishing, Abrasive Grain From G60 to G150) los yog No.4 (Fine Finishing, Most Nrov, abrasive grain from G180 or above) thiab HL Finishing (Hairline Finishing, Characterized by Smooth and kab ntev).ZSSPL yog tsim rau txiasdaim ntawv rau daim ntawv sib tsootxheej txheem los ntawm600 rau2200mm dav thiab thickness ntawm 0.4 mus rau 3.0 hli.

PGL-Grinding Polishing Kab rau Hnyav Phaj

Client:西部金属

Tag Nrho Tsis Siv Neeg Sib Tsoo thiab Polishing Kab yog siv rau kev tshem tawm qhov tsis xws luag los ntawm kub dov, pickling & annealing txheej txheem thiab seem seem, thiab ua tiav qhov thov thickness thiab roughness.Lub coolant tuaj yeem yog emulsion lossis ntxhia roj.Coolant filtration thiab recycling system yog qhov tseem ceeb rau txoj kab tiav.ZSPGLyog tsim los rau kev ua cov kub dov hnyav phaj ntawm 600 mus rau 2200 hli dav thiab ib tug tuab ntawm 1.0 mus rau 30 hli.WUXI ZS kuj muab PGL qhuav.

Daim iav Finishing (8K) Tshuab rau Stainless Hlau Phaj

Client:新华医疗

Qhov zoo ntawm WUXI 25 Daim iav Finishing Tshuab rau Stainless Hlau Chev thiab Ntawv.Polishing taub hau ntawm txhua pab pawg yuav ua tau ntawm nws tus kheej los yog integrally lifted nce thiab nqis.Center refiling ntawm polishing compound kom tsis txhob ntog hauv qab polishing disc tau burnt.Stainless hlau ua.Anti corrosion thiab ntevlub neej.Smooth reciprocating txav los ntawm linear qhia.

Daim iav Finishing Tshuab rau Cold Rolling Coil thiab Sheet

Client: MINOX (INDIA)

Pinch yob hom.Nws siv cov khoom sib tsoo sib tsoo, Scotch-Brite disc, polishing compound muaj 5% Al2O3 + 5% nitric acid + 90% dej los txhim kho qhov roughness ntawm cov kauj ruam los ntawm kauj ruam, thaum kawg super iav tiav tuaj yeem tau txais (8K).

Tsis Siv Neeg Loading / Unloading Device nrog Nqus Khob Pab Pawg

Client:博海金属

Nws muaj lub gantry ncej ua los ntawm welded, carbon steel thiab haum raws li qhov loj me los txhawb kev ua haujlwm kev ntxhov siab.Cov cuab yeej muaj cov pab pawg hauv qab no: chav txhais lus, Lifting unit, Lub tshuab nqus tsev khaws khoom.

Lub tsev txhais lus yog coj los ntawm phau ntawv qhia liner, tsav los ntawm servo lub cev muaj zog ntawm lub iav thiab pinion.Lub lifting unit coj los ntawm cov phau ntawv qhia liner, tsav los ntawm pneumatic piston.Lub tsev khaws khoom yog tsim los ntawm 3 lub tuav tuav tuav nrog 18 lub khob nqus dej, lub bar yog nyob rau hauv ib qho chaw ruaj khov tab sis txhua lub khob nqus dej tuaj yeem txav mus ntev, tus neeg teb xov tooj tuaj yeem tso qhov kev sib tw, kho txoj hauj lwm ntawm lub khob nqus dej, xauv dua. fixture yooj yim.

Txhua lub khob nqus tsev yog txuas nrog rau tus kheej pneumatic piping kom ntseeg tau tias kev ua haujlwm zoo ntawm lub cev, txhua lub khob nqus tau txuas nrog lub caij nplooj ntoos hlav arbor los xyuas kom meej qhov chaw txaus ntawm lub khob thiab ua haujlwm.

Tsis Siv Neeg Laminator rau Zaj Duab Xis (PVC Txheej Tshuab)

Client: STEEL COLOR (ITALY)

Tsis Siv Neeg Laminator / PVC Txheej Tshuab yog siv los ua zaj duab xis Lamination ntawm Sheet Surface.Nws tuaj yeem tsim rau ob sab Ob chav txheej Laminating.

Tsis Siv Neeg Lamination, Tsis Siv Neeg Txiav.

* Tshuab hom: 400-2500 Hom

* Ua haujlwm dav: 400-2500MM

* Ua hauj lwm ceev: Tsau ceev / adjustable ceev

* Daim ntawv thov: Lub tshuab no tsuas yog siv hauv Coiler / De-coiler System,

Polishing Tshuab, 8K Daim iav Polishing Tshuab, Txiav rau Ntev Kab,

Sib tsoo tshuab thiab lwm yam.

* Cov tshuab tuaj yeem tsim kho.